Guaranteed To Remove Rust & Cut Labor Costs

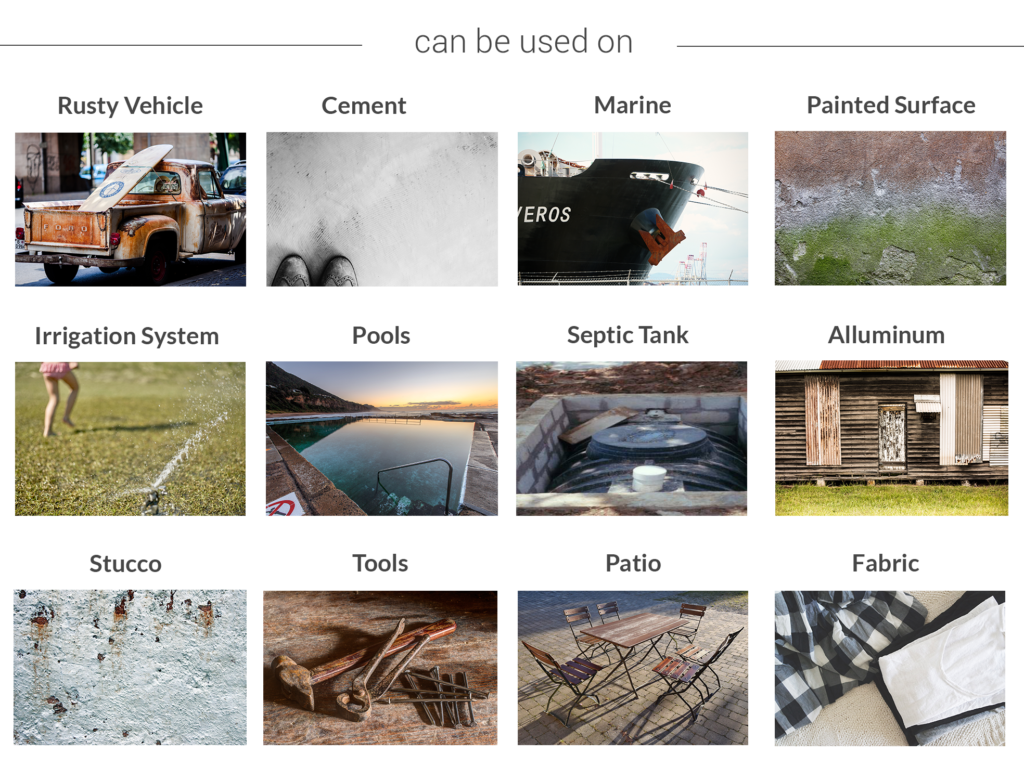

Can Use On

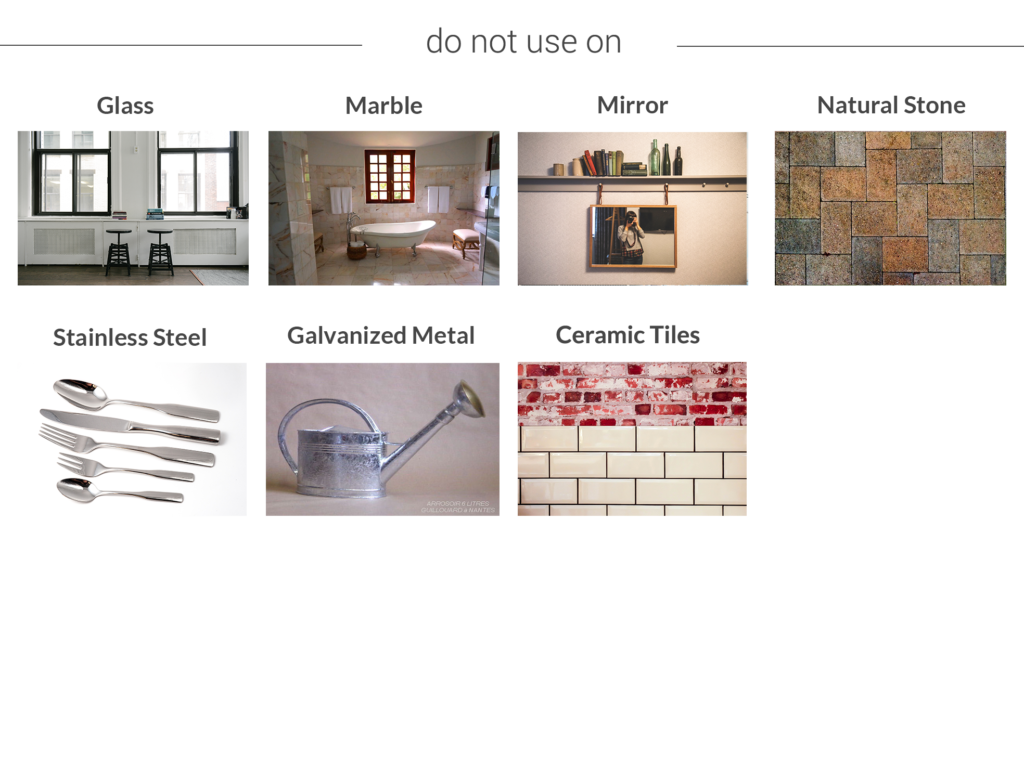

Do Not Use On

Even More Reviews

Frequently

Asked

Questions

Used by professionals, hotels, and now available to the public. Rusterizer is a safe rust, calcium, and lime remover. Here are some common asked questions by new customers.

SALE UP TO 30%

Deal Of The Week

Remove Rust, Lime, & Calcium Without Heavy Scrubbing.